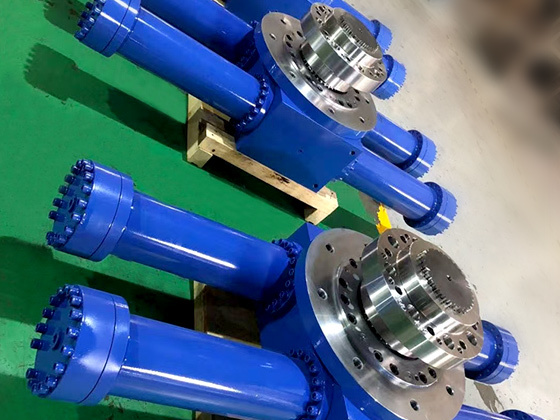

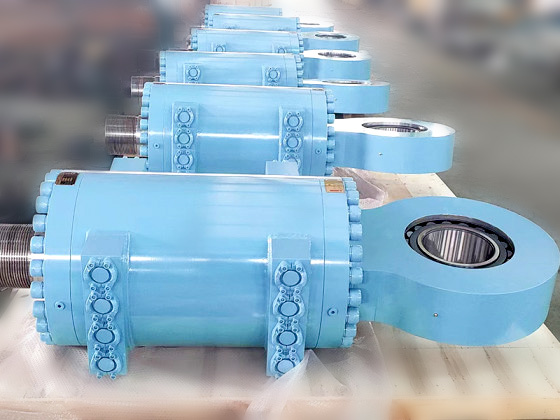

HSG※01 Series Engineering Hydraulic Cylinder

Summary: The main products produced by the company include: hydraulic cylinders, hydraulic systems, earth pressure balance roadheader, mud water balance roadheader and water treatment and other non-standard complete sets of equipment, as well as pneumatic components, various types of shafts, disk processing parts

- Product Description

-

Purpose and Features

HSG※01-E series double-acting single-rod hydraulic cylinder is an actuator that performs reciprocating linear motion in hydraulic systems. It has characteristics such as simple structure, reliable operation, easy assembly and disassembly, easy maintenance, various connection methods, and optional cushioning locations. It is suitable for construction machinery, mining machinery, lifting and transportation machinery, metallurgical machinery, and other machinery industries.

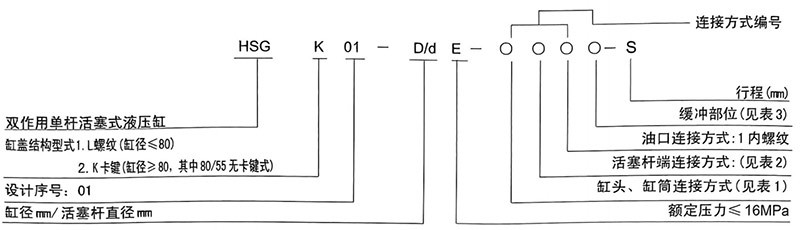

Model Description

Cylinder head and cylinder tube connection method Table 1

Number Connection Method Remarks 1 Cylinder head ear ring with bushing 2 Cylinder head ear ring with joint bearing 3 Hinge shaft For cylinder diameter

D≥φ80

(Refers to key connection)4 End flange 5 Middle flange Piston rod end connection method Table 2

Number Connection Method Remarks 1 External thread at rod end 2 Internal thread at rod end For cylinder diameter D≥φ63 3 External thread rod end ear ring with bushing 4 Internal thread rod end ear ring with bushing For cylinder diameter D≥φ63 5 External thread rod end ear ring with joint bearing 6 Internal thread rod end ear ring with joint bearing For cylinder diameter D≥φ63 7 Integral piston rod ear ring with bushing Only for φ40, 50

Two cylinder diameters8 Integral piston rod ear ring with joint bearing Cushioning location Table 3

Number Location Remarks 0 No cushioning Cylinder diameters φ40, φ50, φ63 without cushioning 1 Cushioning at both ends When speed ratio φ=2, only the cylinder bottom end has cushioning 2 Cushioning at the cylinder bottom end 3 Cushioning at the rod head end Selection Instructions

1. Users should refer to the "Model Description" according to their needs, check Tables 1 to 3 based on connection methods and cushioning locations, then write down the connection method and cushioning location numbers, determine the required structural type, and based on the structural type, cylinder diameter, speed ratio, etc., determine the external installation connection dimensions.

2. When ordering, specify the complete model and selected stroke, installation distance.

Product code - main parameters - connection method and cushioning location number - stroke × installation distance

Note: If the required installation distance matches the installation distance in Tables 1 to 4, it can be omitted when ordering; if not, it must be specified. However, the required installation distance can only be selected according to the specified range in Tables 1 to A.

Example: A user needs a hydraulic cylinder. The cylinder head structural type is key type, the cylinder tube is connected by a middle flange, without cushioning, the piston rod has an internal thread at the rod end, the cylinder diameter is 80mm, rod diameter φ40mm, stroke 1000mm, installation distance L13=500mm, the order model is: HSGK01-80/40E-5210~1000×500

Key words:

Non-standard complete sets of equipment such as hydraulic cylinder, hydraulic system, earth pressure balance roadheader, mud water balance roadheader and water treatment, as well as pneumatic components, various shafts and plates

Product inquiry

The main products produced by the company include: hydraulic cylinder, hydraulic system, earth pressure balance roadheader, mud water balance roadheader and water treatment and other non-standard complete sets of equipment, as well as pneumatic components, various types of shaft, plate processing parts.

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas